Having a Continuous Improvement Process mindset is essential in the Fourth Industrial Revolution. One has to be intuitive enough to deal with the intricacies of systems, people, policies and processes whilst still driving change, collaboration and innovation across functions.

As Continuous Improvement Manager for a Food Manufacturing company or almost 8 years, “Patti” helps teams kick start projects in the right direction, run deep dives into project scope and unpacks the complex business landscape from production to waste management using a range of facilitated activities as part of her team meetings.

With specializations in Lean Manufacturing, Operations, Supply Chain Optimization, Coaching, Goods Manufacturing Practice, and Team Building, she uses Six Sigma and continuous improvement methods to provide measurable and sustainable improvements across behavioural, systems, process and regulatory processes.

With specializations in Lean Manufacturing, Operations, Supply Chain Optimization, Coaching, Goods Manufacturing Practice, and Team Building, she uses Six Sigma and continuous improvement methods to provide measurable and sustainable improvements across behavioural, systems, process and regulatory processes.

We reached out to Patti to understand more about how she used GroupMap and to get ideas about what was and was not working for her. With her permission, we’ve been able to share extracts of that interview below.

What kind of team-based activities and meetings do you run?

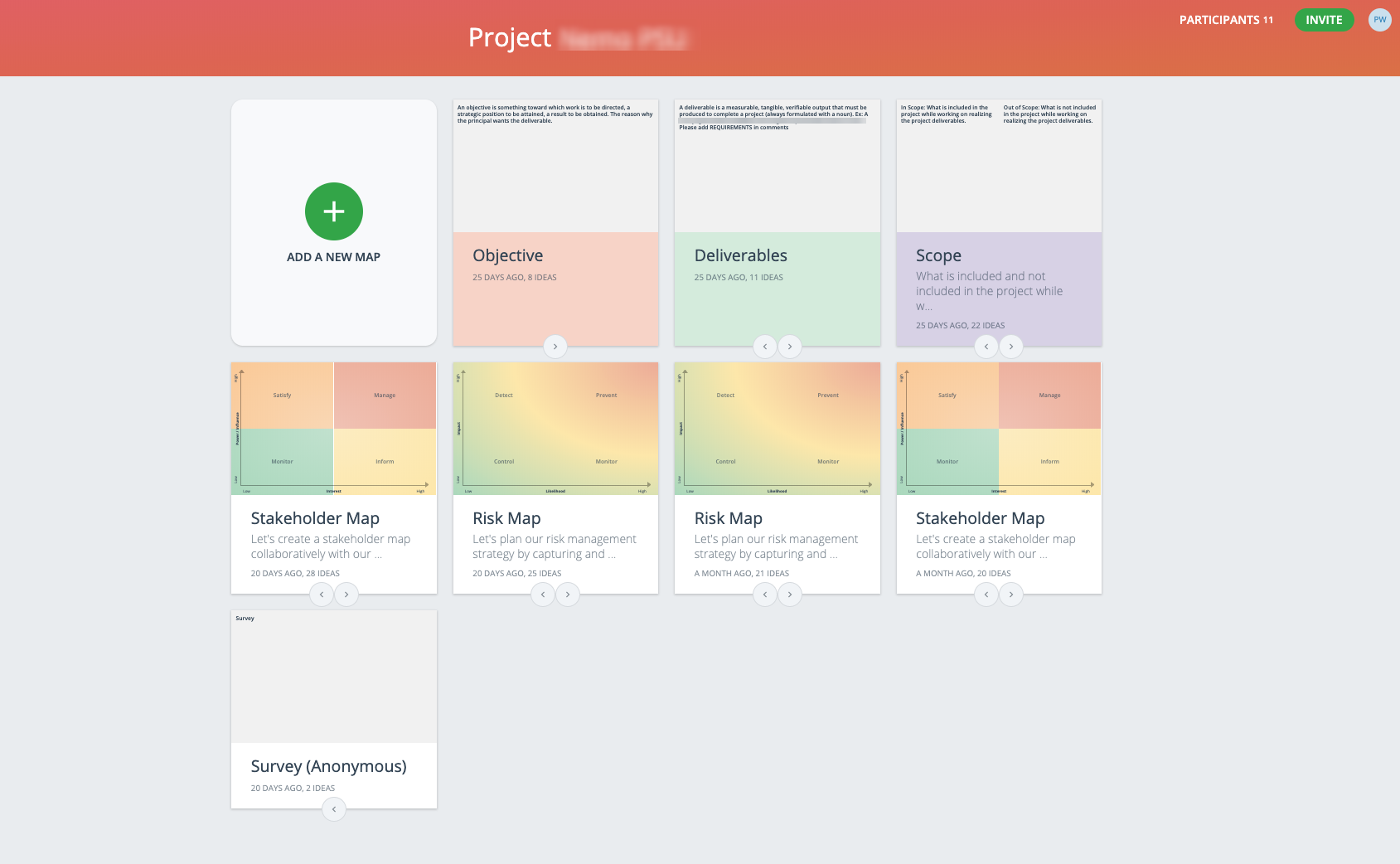

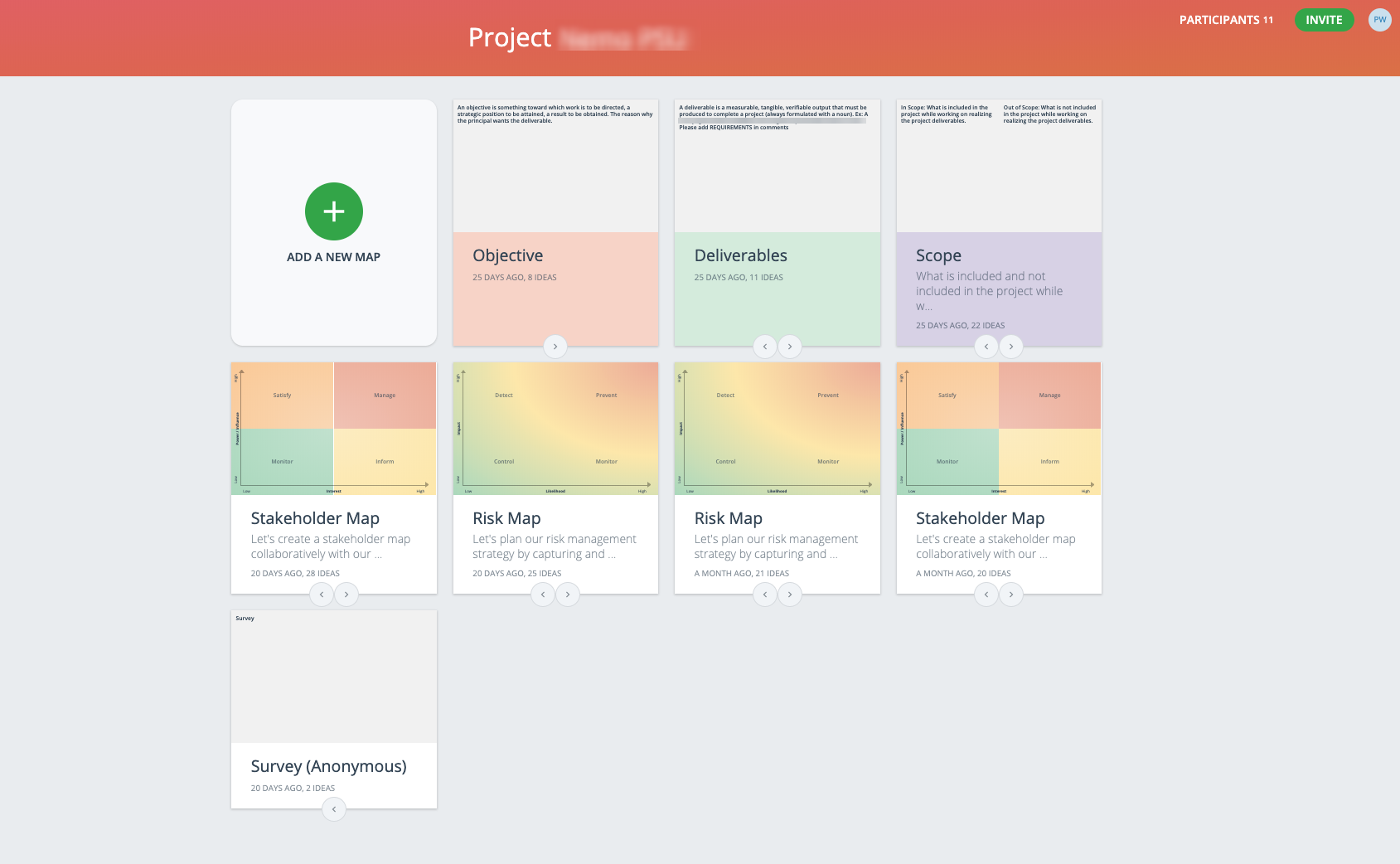

I run project startup and kick-off meetings to help make sure that people are aligned and working on the right solution from the very beginning. This includes defining objectives and deliverables for projects and helping them clearly define them.

Examples of this process include Stakeholder Maps, Risk Maps and tactical shutdown protocols. From a strategic planning process, we might use SWOT Analysis as well as group ratings of strategies for decision making.

In terms of reflective practice, this includes the 4L’s, starfish retrospectives and MoSCoW (Must, Should, Could, Won’t) to name a few. We would take our teams through a process to share what they have learned from our projects and decide on what we needed to start doing, stop doing, keep doing as well as what we needed to do more or less of.

In terms of reflective practice, this includes the 4L’s, starfish retrospectives and MoSCoW (Must, Should, Could, Won’t) to name a few. We would take our teams through a process to share what they have learned from our projects and decide on what we needed to start doing, stop doing, keep doing as well as what we needed to do more or less of.

At the last meeting, for example, we had 22 people in a team, who come up with 74 action items based on what we had shared from our initial learning and brainstorming event.

In terms of more ad hoc event, we would use the Impact Effort Matrix to help prioritize our different strategies or projects or develop a continuous improvement plan based on cycle periods. This is a really great way to help teams see the larger picture and to help plan and prioritize our activities overall as well as making sure people across areas are aligned.

What are some of the practices you use as a CI (Continuous Improvement) Manager?

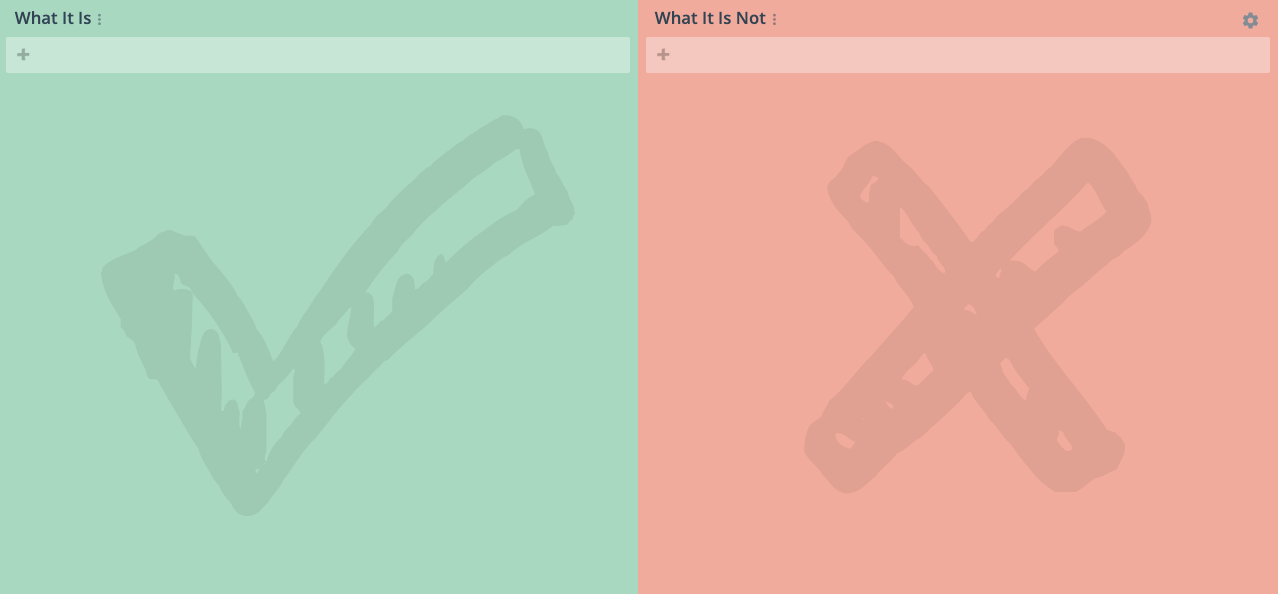

As a CI Manager, one of my key roles is to clearly define problem statements by understanding the scope of the project. For example, when a vision or goal starts to form, I lead them by breaking down the project into what it IS and what it IS NOT. It sounds simple enough but it can lead to some great discussion so it is a great way to manage project scope and to help the team better crystalize and visualize it.

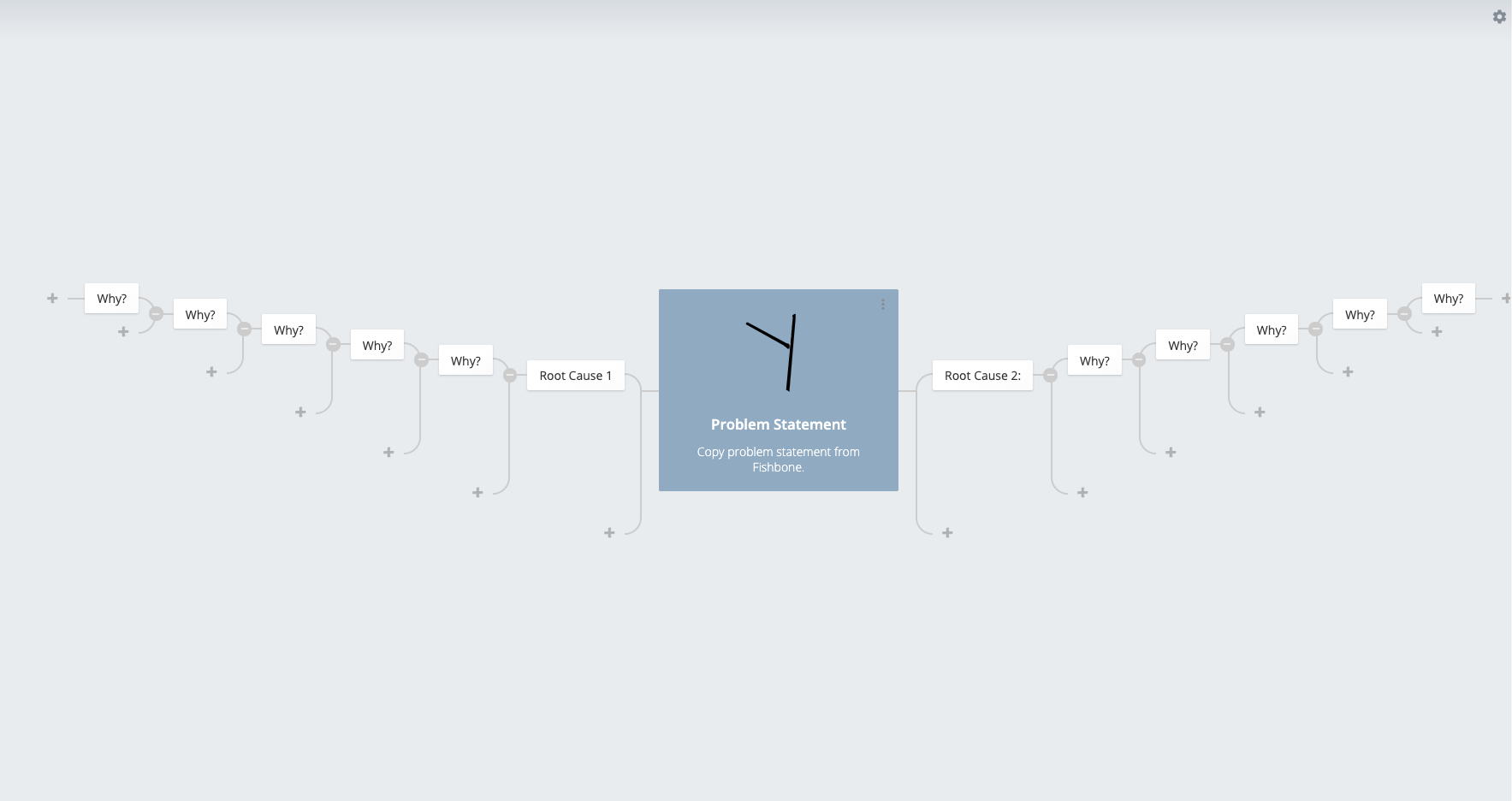

When troubleshooting, I like using a mind map with a root cause that branches out with 5 WHYs to allow people to find root causes of issues and to be able to see the flow-on impacts. The flexibility of being able to add multiple root causes and then have as many WHYs as needed enables every team member to really understand the problem. You identify the original concern and then you can start to deep dive as far as needed to get to the root cause, without being limited or confirming specifically to 5.

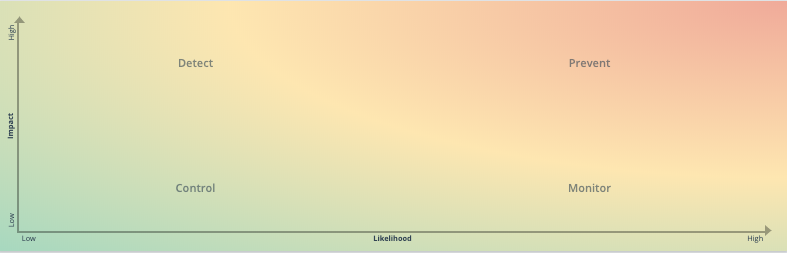

For prioritizing ideas, I use Rate by Impact vs Implementation matrix with the team to help prioritize which activities we should focus on, the sequence and how we need to allocate our time and resources.

The means that we would take the action items that were seen to have the highest {positive} impact on the project with the least barriers to implement as our low hanging fruit and put those into action first. We could then do deep-dive discussions over the remaining items as well as filter out the items that would have the least {positive} impact and would be the hardest to implement.

What are some of your “Go-to” questions when talking to your team?

I would say that my top 5 would generally be questions like…

- What are our main objectives and deliverables?

- What are things that are a must-have versus nice to have?

- Who are we doing this for?

- What does success look like for us?

- How do we do this and how much should we do?

In terms of how we run sessions, we might start with a little ice breaker as a meet and greet and to get the team started with the session. We then decide on key objectives based on what has been given to us by our Principals and flesh out the expected deliverables required. This helps us determine the scope of the activities.

Following this, we are able to break down requirements for certain key requirements to reduce risk and remove uncertainty as well as looking for any constraints that might impede on our program.

Finally, we go through an exercise looking at the interrelations between processes or other projects that would otherwise impact the time, budget or quality of the project.

What have been some of your experience using GroupMap with your team so far?

Having facilitated a range of activities for the past 20 years, I was shocked when I realized I was still using the same old process. Sticky notes and markers can only go so far and using online meeting facilitation tools like GroupMap has made my facilitation process easier and quicker. One of the attendees at my workshop came up and said he was so happy because on the plane ride home he would actually get to watch a movie because the work had been done and he didn’t have to re-write notes and ideas from photographs of post-it notes.

There has been a BIG increase in participation of members and ideas produced. At the end of each event, we generate PDFs and excel files for each group map and then share them with the project owners for easier review of their brainstorming activity. It feels like we may be getting 25% more ideas when using GroupMap compared to traditional brainstorming methods.

My colleagues are super positive too. One said, my team and I are absolutely loving this tool! Today I put together some new templates based on some problem-solving models including a 5 Why MindMap and a Cause and Effect Diagram. We are piloting the use of GroupMap to help our root cause analysis structure.“

Another said, “GroupMap has added an incredible amount of value to our manufacturing facility. I am looking forward to finding even more ways to incorporate it in our processes.”

What would be your top 3 tips as a to other users of GroupMap?

- Create as many templates as possible to save time!

- Import ideas from map to map and arrange them differently to generate a new conversation. Don’t waste time retyping the same information over and over.

- Push your creativity, look at what processes you can bring into GroupMap to make the process of problem-solving or continuous improvement more effective. It is a HUGE time saver.

This article has been anonymized at the client’s request. All practices, outcomes and feedback was shared through a series of interviews, emails and meeting evaluations.

Get Started Now

Ready to use some continuous improvement strategies with your team? Try GroupMap for your next meeting or workshop. . Log in, Start a 14 day free trial or contact us for more information.